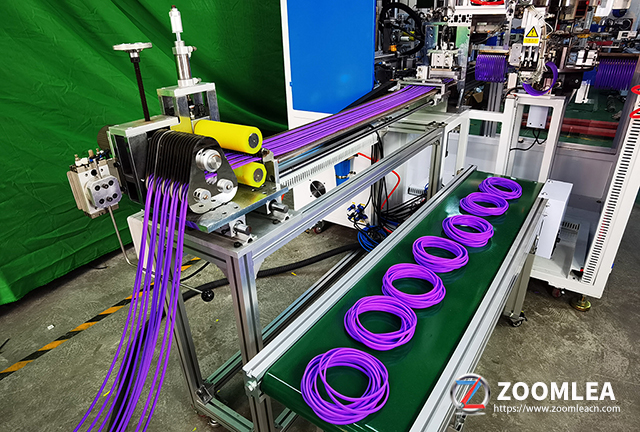

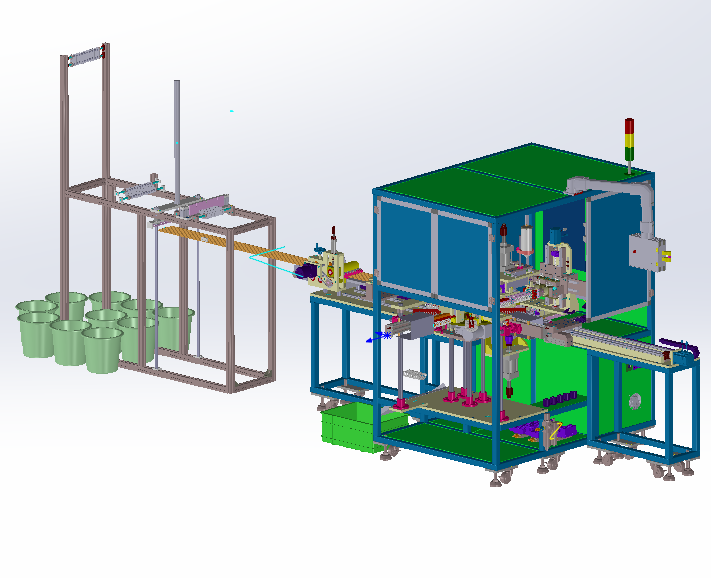

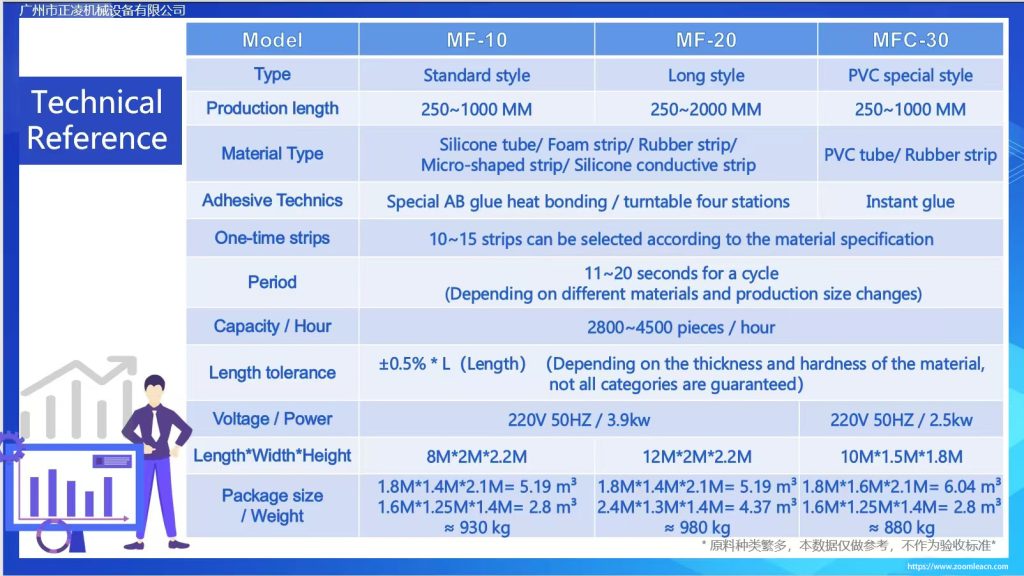

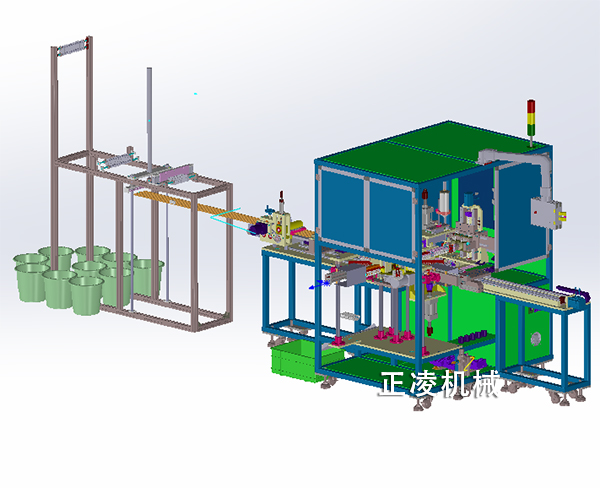

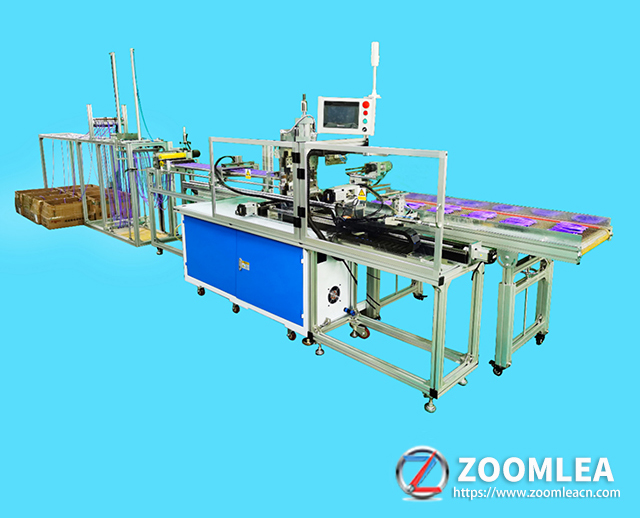

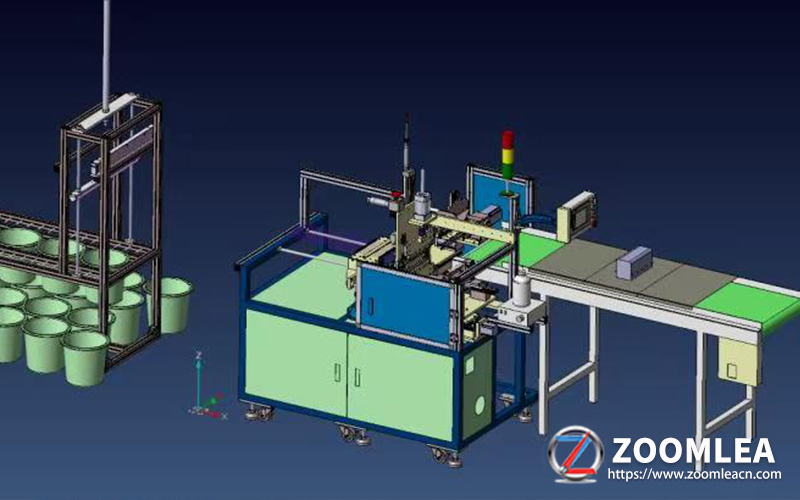

Fully automatic silicone sealing ring bonding machine

Automatic silicone sealing ring cutting and bonding machine is a new type of equipment launched by our company, which has national intellectual property rights/patents, and can be widely used in silicone sealing strip/sealing ring industry.

The main material of the sealing strip bonding machine is carbon steel frame, aluminum alloy, the driving mode is servo motor, stepping motor, cylinder, electrical appliances, divided into short and long models, the raw material type is hollow silicone strip, shaped silicone strip.

The sealing strip bonding machine produces 10 pieces each time, 10 seconds a cycle, equivalent to 1 piece/second, 3600 pieces per hour, and the daily output reaches 86,000.

Product features:

1, the integration of cutting, bonding two processes, integration, from the complete sealing strip, directly made into the sealing ring finished products.

2, maximum use of CNC structure, easy to adjust the size

3, easy to replace the mold, through a long time test, easy to operate

4, professional engineers R & D control, materials and materials, good stability

5. Safe, stable and efficient

Product advantages:

1, the process is simple: traditional process (two processes, first machine cut, then manually bonded)

Machine production (one process, machine cutting and bonding integration)

2, less labor: traditional process (machine cutting needs 1 person, artificial bonding depending on the scale of the factory, less than ten or twenty, more than dozens of people)

Machine production (1 person to operate a machine, 1 machine can replace 8 people)

3, the use of small site: traditional process (dozens of hundreds of people of the factory, two processes of the material need to constantly turnover, the use of large site)

Machine production (one machine integrates two processes, the material does not need to turnover site, the personnel is compressed, the use of space is greatly reduced, the rent is reduced)

4, less management costs: traditional technology (more personnel, more equipment, large venues, high management costs)

Machine production (less personnel, less equipment, small site, effectively saving management costs)

5, reduce labor factors: traditional technology (labor-intensive mode of production, product capacity and quality are greatly affected by the mood and state of personnel)

Machine production (machine production, less labor, affected by the emotional state of personnel as little as possible)

6, high production efficiency: traditional industries (labor-intensive, low per capita production efficiency, high production costs)

Machine production (the machine produces 10 pieces at a time, 10 seconds a cycle, equivalent to 1 piece/second, production efficiency leaps several levels)

7, stable quality: traditional process (manual quality, different people, different time periods and different semi-automatic equipment, resulting in uneven quality)

Machine production (mechanized production, one person, one machine, quality is guaranteed, stable and beautiful)

Zoomlea automatic silicone seal bonding machine adopts the cutting and bonding integration process, reduces the repetitive labor rate of employees, improves the effective use of human resources, greatly liberates the productivity, improves the production capacity, and also guarantees the product quality at a deeper level, so as to achieve stability, high quality, high yield and high efficiency.

Guangzhou Zoomlea Machinery Equipment Co., Ltd. is committed to continuously improving production efficiency, reducing costs, improving profit margins, and fundamentally improving customers’ market competitiveness.

English/product/fully-automatic-silicone-sealing-ring-bonding-machine/

English/product/fully-automatic-silicone-sealing-ring-bonding-machine/ Afrikaans/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=af

Afrikaans/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=af አማርኛ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=am

አማርኛ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=am Հայերեն/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=hy

Հայերեն/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=hy azərbaycan dili/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=az

azərbaycan dili/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=az Euskara/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=eu

Euskara/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=eu বাংলা/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=bn

বাংলা/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=bn bosanski jezik/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=bs

bosanski jezik/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=bs မြန်မာစာ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=my

မြန်မာစာ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=my 粤语/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=yue

粤语/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=yue 中文(简体)/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=zh

中文(简体)/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=zh 中文(漢字)/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=zh-tw

中文(漢字)/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=zh-tw Hrvatski/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=hr

Hrvatski/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=hr Čeština/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=cs

Čeština/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=cs Dansk/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=da

Dansk/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=da Esperanto/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=eo

Esperanto/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=eo Suomi/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=fi

Suomi/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=fi Français/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=fr

Français/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=fr Frysk/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=fy

Frysk/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=fy Deutsch/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=de

Deutsch/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=de Harshen Hausa/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ha

Harshen Hausa/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ha Hmoob Daw/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mw

Hmoob Daw/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mw Мары йӹлмӹ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mrj

Мары йӹлмӹ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mrj Íslenska/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=is

Íslenska/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=is Bahasa Indonesia/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=id

Bahasa Indonesia/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=id Gaeilge/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ga

Gaeilge/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ga Italiano/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=it

Italiano/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=it 日本語/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ja

日本語/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ja basa Jawa/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=jw

basa Jawa/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=jw Қазақ тілі/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=kk

Қазақ тілі/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=kk ភាសាខ្មែរ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=km

ភាសាខ្មែរ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=km кыргыз тили/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ky

кыргыз тили/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ky 한국어/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ko

한국어/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ko ພາສາລາວ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=lo

ພາສາລາວ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=lo Latīna/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=la

Latīna/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=la македонски јазик/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mk

македонски јазик/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mk Malagasy fiteny/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mg

Malagasy fiteny/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mg Bahasa Melayu/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ms

Bahasa Melayu/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ms മലയാളം/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ml

മലയാളം/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ml Malti/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mt

Malti/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mt मराठी/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mr

मराठी/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mr марий йылме/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mhr

марий йылме/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=mhr नेपाली/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ne

नेपाली/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ne Norsk/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=no

Norsk/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=no Polski/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=pl

Polski/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=pl Português/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=pt

Português/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=pt ਪੰਜਾਬੀ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=pa

ਪੰਜਾਬੀ/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=pa Română/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ro

Română/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ro Русский/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ru

Русский/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ru Sesotho/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=st

Sesotho/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=st سنڌي/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=sd

سنڌي/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=sd Slovenčina/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=sk

Slovenčina/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=sk Slovenščina/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=sl

Slovenščina/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=sl Español/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=es

Español/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=es Svenska/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=sv

Svenska/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=sv Reo Mā`ohi'/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ty

Reo Mā`ohi'/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ty தமிழ்/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ta

தமிழ்/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ta ภาษาไทย/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=th

ภาษาไทย/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=th faka Tonga/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=to

faka Tonga/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=to اردو/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ur

اردو/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=ur Tiếng Việt/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=vi

Tiếng Việt/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=vi isiXhosa/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=xh

isiXhosa/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=xh èdè Yorùbá/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=yo

èdè Yorùbá/product/fully-automatic-silicone-sealing-ring-bonding-machine/?lang=yo

MESSAGE